Orange TGLL, also known as Direct Orange 34, is a synthetic azo dye widely utilized in various industries for its vibrant orange hue and effective dyeing properties.

Synonyms

- Direct Orange 34

- C.I. 40215

- Perfinaze Orange TGLL (Y)

- Direct Orange TGLL

- Orange TGLL

Chemical Identifiers

- Chemical Name: Benzenesulfonic acid, 2,2′-(1,2-ethenediyl)bis[5-nitro-, reaction products with methylated 4-[(4-aminophenyl)azo]benzenesulfonic acid monosodium salt

- CAS Number: 12222-37-6

- EC Number: 235-415-8

- Molecular Formula: C₃₃H₂₄N₆O₉S₂·2Na

- Molecular Weight: 758.68 g/mol

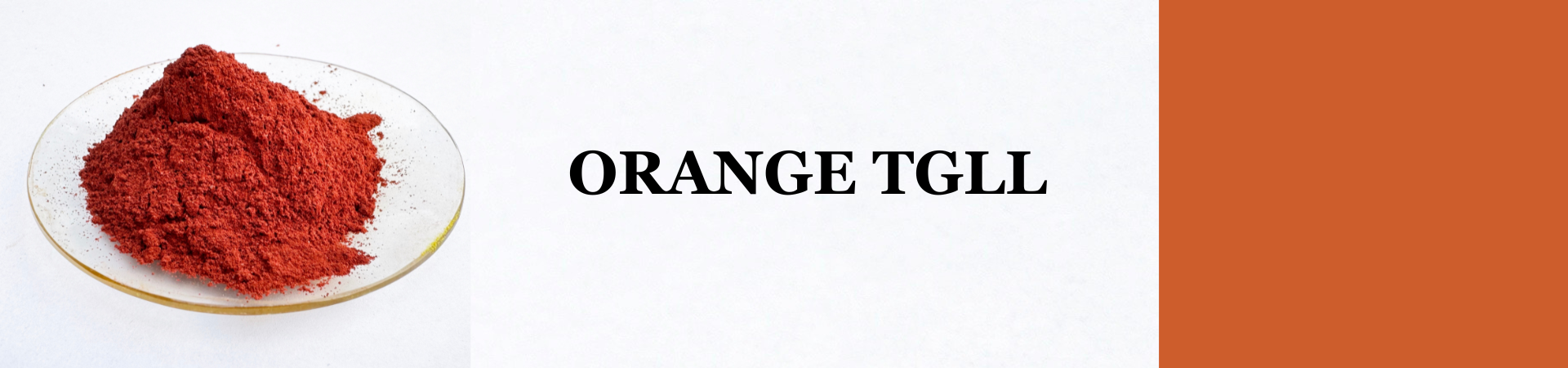

Physical and Chemical Properties Appearance

Orange powder

Solubility: Soluble in water (80 g/L at 90°C)

Insolubles: 0.15% w/w

Light Fastness: 6 (on a scale where higher values indicate better fastness)

Washing Fastness: 6

Perspiration Fastness: 3

Applications

Orange TGLL is primarily used for dyeing cellulosic fibers, including:

Cotton, Wool, Viscose Rayon,

Silk

Flax

Paper

Leather

Plastic

Acetate

Jute

Its excellent solubility and dyeing properties make it suitable for various industrial applications.

Orange TGLL

One well-known dye through direct dye class is Orange TGLL, sometimes referred to as Direct Orange 34. It is widely used in several industries, especially textiles, due to its adaptability and comparatively simple application. The characteristics, uses, benefits, and safety issues related to Orange TGLL will all be covered in this blog post.

Chemical Characteristics and Properties:

Reddish-orange powder is how Orange TGLL looks. When dissolved in water, it forms a golden-brown solution. Its use in dyeing processes depends on its solubility. Because it constitutes a direct dye, it may attach itself to cellulose fibres directly without the need for a mordant, which is a chemical that fixes dyes. This makes the dying process easier and helps make it more affordable.

Orange TGLL’s strong lightfastness—which means it doesn’t fade in the presence of light—and moderate wash-fastness—which means it keeps its colour after washing—are two of its key qualities.

Applications in Various Industries:

There are several different applications for orange TGLL:

- Paper Dyeing

- Leather Dyeing

- Other Uses

Orange TGLL benefits:

Orange TGLL is widely used because to a number of factors:

Cost-Effectiveness: Compared to other dye classes, direct dyes are typically less expensive. Because of this, Orange TGLL is an affordable choice, especially to large-scale dyeing initiatives where financial concerns are crucial.

Application Ease: By applying Orange TGLL directly to cellulose fibres, mordants are not necessary, which streamlines the dyeing procedure and uses less time and resources.

Good Lightfastness: The dye’s ability to resist fading in the presence of light guarantees the material being dyed materials will keep what they are. vivid colour for an extended amount of time, increasing the product’s durability and attractiveness.

Versatility: Orange TGLL is a versatile dye that may be used in a variety of sectors due to its capacity to dye a wide range of materials, among them textiles, paper, and leather.

Precautions for safety and handling:

Despite its widespread use, Orange TGLL must be handled carefully and in accordance with safety precautions:

- Protective Gear

- Ventilation

- Handling Protocols

In summary

Orange TGLL is a cost-effective and adaptable dye that has several uses, especially in the textile sector. It is a common option when dyeing cotton, viscose, & rayon because of its straight application to cellulose fibres and its lightfastness. Orange TGLL has several benefits, but in order to maintain a safe working environment, it must be handled carefully and in accordance with safety regulations. To maximise its advantages and reduce any potential risks, it is essential to comprehend its characteristics, uses, and safety issues.